Profile optimization parameters

From Opera Wiki

(Difference between revisions)

| Line 31: | Line 31: | ||

<!--[[File:taglioott3.png|thumb|right|300px|Esempio di Taglio ottimizzato al pezzo]]--> | <!--[[File:taglioott3.png|thumb|right|300px|Esempio di Taglio ottimizzato al pezzo]]--> | ||

:*'''List''':This allows to create a list of maximal measures put on disposal by the supplier. Such measures are analyzed by the program which will take the fittest bar to order in the optimization stage. | :*'''List''':This allows to create a list of maximal measures put on disposal by the supplier. Such measures are analyzed by the program which will take the fittest bar to order in the optimization stage. | ||

| - | + | :*'''Per part''': This allow to optimize and hence to order the bar, in the real measure of use | |

<!-- HELP: JM/W2901 --> | <!-- HELP: JM/W2901 --> | ||

[[Category: JM/Manual]] | [[Category: JM/Manual]] | ||

Revision as of 14:12, 16 May 2011

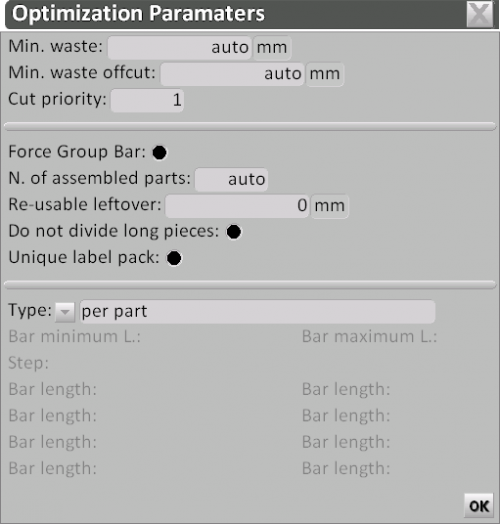

This window is used to customize the optimization data for a profile.

Content description

- Min waste: the minimum allowed waste for the profile

- Min waste offcut: the maximum waste during the optimization of the offcuts

- Cut priority: sort position for the cutting list

- Force group bar: if enabled, bars are cut together even when more bars than necessary are required

- N. of assembled parts: the number of bars to cut together

- Re-usable leftover: the minimum lenght of the leftover to utilize again

- Do not divide long pieces: If enabled, long workpieces are not shared out amid the bars to be optimized

- Unique label pack: If enabled, Opera will print out a unique label for the grouped cut

- None

- do not use any optimization on bars

- Interval: :Choosing this kind of optimization, it’s possible to determine both the minimal and the maximal measure put on disposal by the supplier, and a step of change of the optimization measures. Following this procedure the program draws the best possible measure for the needed bar.

- List:This allows to create a list of maximal measures put on disposal by the supplier. Such measures are analyzed by the program which will take the fittest bar to order in the optimization stage.

- Per part: This allow to optimize and hence to order the bar, in the real measure of use