Profile optimization parameters

From Opera Wiki

(Difference between revisions)

Monica.Sanna (Talk | contribs) |

|||

| (5 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

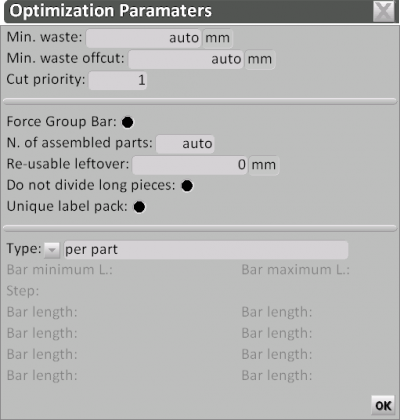

| - | [[File:quadroparametriottimizzazione.png|thumb|right| | + | [[File:quadroparametriottimizzazione.png|thumb|right|400px|The Optimization Parameters Panel]] |

| - | {{NB|To access this | + | {{NB|To access this panel in Opera Order Management: from the ''Archives'' menu, select the ''Profiles'' button, and in the following panel click the [[Image:tastoottimizza.png]] button}} |

| - | + | The purpose of this panel is to allow a form of optimization customization. | |

| - | ''' | + | *'''Reversible''' |

| + | :Indicates to the program whether the profile is reversible or not. The reversibility property of a profile—applicable to Z‐profiles—means it can be used the same way even when flipped. The program uses this property when calculating the optimized cut to avoid creating useless offcuts. | ||

| + | |||

| + | <gallery> | ||

| + | File:profiloz.png|Example of a reversible profile | ||

| + | File:barrareversibile.png|Example of bar optimized with a reversible profile | ||

| + | File:barrareversibile2.png|Example of bar optimized with a NON-reversible profile | ||

| + | </gallery> | ||

| + | |||

| + | *'''Symmetric''': Profile symmetric with respect to the inside and outside surfaces | ||

| + | *'''Min. offcut''': the minimum waste length in profile optimization | ||

| + | *'''Min. offcuts for offcuts''': the minimum waste length in segment optimization | ||

| + | *'''Minimum leftover''':The value of the smallest reusable segment. The ''Auto'' setting means the profile adopts the value set in the cutting parameters; see also the '''Cutting''' section in the '''Options''' chapter. | ||

| + | *'''Cut priority''' (Ord.tgl.): the order position for cutting | ||

| + | *'''No ID code''': do not generate an identification code for this profile in technical prints | ||

| + | *'''Force bar grouping''': when this box is checked, the program optimizes by always cutting bars grouped together—even when a single bar would suffice—so the optimization is printed as shown in the images below, depending on the setting. | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

{|style=float:left | {|style=float:left | ||

| - | |[[File:taglioott.png|thumb|left|300px| | + | |[[File:taglioott.png|thumb|left|300px|Example of optimized cut with 1 grouped piece and ‘Force bars together’ unchecked]] |

| - | |[[File:taglioott2.png|thumb|left|300px| | + | |[[File:taglioott2.png|thumb|left|300px|Example of optimized cut with 2 grouped pieces and ‘Force bars together’ checked]] |

|} | |} | ||

| - | |||

{{BR}} | {{BR}} | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | + | *'''N. of assembled parts''': Enabling these boxes (active if the previous option is selected) allows optimizing the cut of multiple bars together in the same bill of materials. If bars need to be cut to identical lengths, simply specify the quantity here. This function is especially useful for profiles traditionally cut in groups, such as blind slats or glazing beads. | |

| - | *''' | + | *'''Re-usable leftover''': For Warehouse Management users, this function lets you set the minimum size of a reusable segment, distinct from the standard size defined in the Cutting Parameters. |

| - | + | *'''Do not divide long pieces''': Checking this field tells the program not to split long pieces across different bars in the optimization. | |

| + | *'''Alert on long pieces''': Checking this field generates an error message in prints if there are long pieces. | ||

| + | |||

| + | *'''Unique label for groups''': This field tells the program to generate a single label for grouped cut pieces, useful for blind slats, glazing beads, etc. | ||

| + | |||

| + | {{NB|The following bar optimization settings become available after installing the Smart optimization advanced step}} | ||

| + | |||

| + | *'''Type'''[[File:frecciagiu.png]]: In this field you can choose the optimization type from the following: | ||

| + | {{BR}} | ||

:;'''Interval''' | :;'''Interval''' | ||

| - | : | + | :Selecting this type of optimization activates the fields '''Min. bar length, Max. bar length, Step''', where you can set a minimum and maximum bar length available from the supplier, and a step increment. With this setting, the program determines the best bar length to use. |

| - | + | [[File:taglioott3.png|thumb|right|300px|Example of piece‐based optimized cut]] | |

| + | |||

:;'''List''' | :;'''List''' | ||

| - | :This | + | :This optimization type activates the '''Bar length''' field and lets you create a list of maximum bar lengths provided by the supplier. The program analyzes these lengths to find the best one to order during optimization. |

| - | + | ||

| - | + | ||

| - | + | ||

| + | :;'''per part''' | ||

| + | :This optimization type lets you optimize—and thus order—material based on the actual length used.<br/> | ||

| + | :;'''Cutting''' | ||

| + | :This optimization type lets you perform a piece‐based optimization according to the real cutting length, with zero waste.<br/>(see also how to set the [[Cutting Parameters|cutting parameters]])<br/> | ||

<!-- HELP: JM/W2901 --> | <!-- HELP: JM/W2901 --> | ||

| + | |||

[[Category: JM/Manual]] | [[Category: JM/Manual]] | ||

Latest revision as of 14:13, 6 May 2025

The purpose of this panel is to allow a form of optimization customization.

- Reversible

- Indicates to the program whether the profile is reversible or not. The reversibility property of a profile—applicable to Z‐profiles—means it can be used the same way even when flipped. The program uses this property when calculating the optimized cut to avoid creating useless offcuts.

- Symmetric: Profile symmetric with respect to the inside and outside surfaces

- Min. offcut: the minimum waste length in profile optimization

- Min. offcuts for offcuts: the minimum waste length in segment optimization

- Minimum leftover:The value of the smallest reusable segment. The Auto setting means the profile adopts the value set in the cutting parameters; see also the Cutting section in the Options chapter.

- Cut priority (Ord.tgl.): the order position for cutting

- No ID code: do not generate an identification code for this profile in technical prints

- Force bar grouping: when this box is checked, the program optimizes by always cutting bars grouped together—even when a single bar would suffice—so the optimization is printed as shown in the images below, depending on the setting.

File:Taglioott.png Example of optimized cut with 1 grouped piece and ‘Force bars together’ unchecked | File:Taglioott2.png Example of optimized cut with 2 grouped pieces and ‘Force bars together’ checked |

- N. of assembled parts: Enabling these boxes (active if the previous option is selected) allows optimizing the cut of multiple bars together in the same bill of materials. If bars need to be cut to identical lengths, simply specify the quantity here. This function is especially useful for profiles traditionally cut in groups, such as blind slats or glazing beads.

- Re-usable leftover: For Warehouse Management users, this function lets you set the minimum size of a reusable segment, distinct from the standard size defined in the Cutting Parameters.

- Do not divide long pieces: Checking this field tells the program not to split long pieces across different bars in the optimization.

- Alert on long pieces: Checking this field generates an error message in prints if there are long pieces.

- Unique label for groups: This field tells the program to generate a single label for grouped cut pieces, useful for blind slats, glazing beads, etc.

- Interval

- Selecting this type of optimization activates the fields Min. bar length, Max. bar length, Step, where you can set a minimum and maximum bar length available from the supplier, and a step increment. With this setting, the program determines the best bar length to use.

File:Taglioott3.png

Example of piece‐based optimized cut

- List

- This optimization type activates the Bar length field and lets you create a list of maximum bar lengths provided by the supplier. The program analyzes these lengths to find the best one to order during optimization.

- per part

- This optimization type lets you optimize—and thus order—material based on the actual length used.

- Cutting

- This optimization type lets you perform a piece‐based optimization according to the real cutting length, with zero waste.

(see also how to set the cutting parameters)