Timing

From Opera Wiki

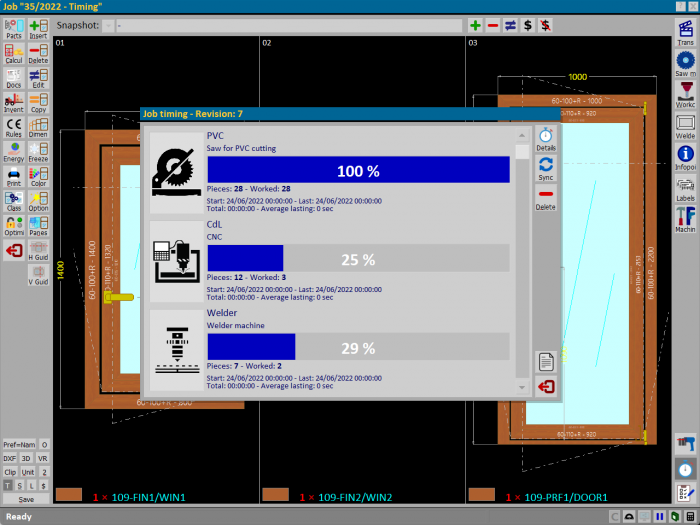

The job Timing panel allows you to check the progress of production in the workshop. The Opera Job Management software allows, through a special connection protocol with the machines, to receive useful information for the recognition of machined parts. This is done through the use of barcodes, which are already present within the software and allow the identification of a part with a unique code.

From the screen, using the synchronisation button, it is possible to start data reading in the machine. In this way, Opera searches for new data on all machines and inserts them into the database, saving the information received. Synchronisation can take place via the operac.exe application, which can be set to start synchronisation at preset time intervals.

: The detail button allows you to check exactly which articles have been handled in production for that specific machine.

: The detail button allows you to check exactly which articles have been handled in production for that specific machine.

: The synchronisation button starts synchronisation with all machines set up for timing management.

: The synchronisation button starts synchronisation with all machines set up for timing management.

: The delete button allows you to delete any possible incorrect timing generation.

: The delete button allows you to delete any possible incorrect timing generation.

: The register button stores the previous readings made by Opera with the machines.

: The register button stores the previous readings made by Opera with the machines.

: The exit button allows you to close the screen

: The exit button allows you to close the screen

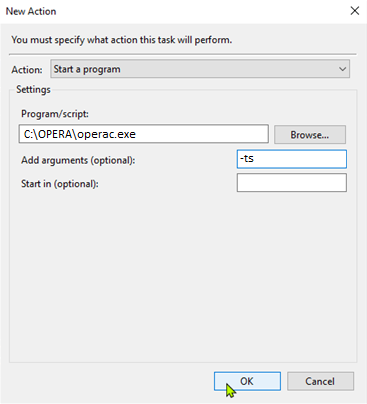

Scheduled synchronisation

Scheduled synchronisation allows Opera to read the data in the machines, always having an updated situation of the work done in production.It can be set up through a utility already present in Windows, called 'Planning Utility', in which a new task can be created, setting the parameters for the automatic start of operac, the application that will manage the import of data from production.