Panel machining

From Opera Wiki

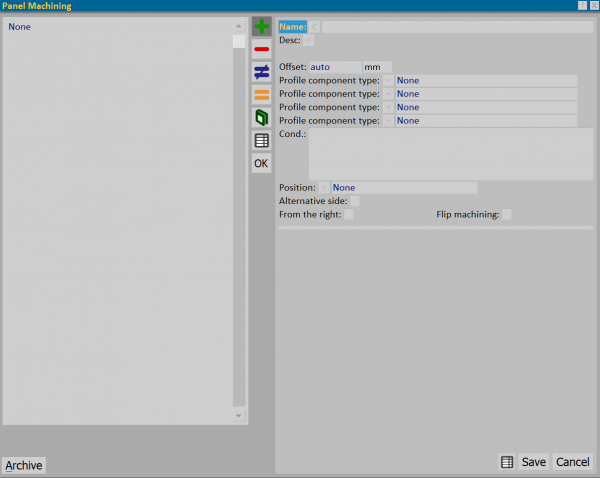

Below is a description of the contents of the framework:

Section 1: Function keys

- The button

is to start loading a new entry.

is to start loading a new entry.

- The button

is used to delete an entry from the archive.

is used to delete an entry from the archive.

- The button

is used to change the data of an entry.

is used to change the data of an entry.

- The button

is used to copy data from an entry.

is used to copy data from an entry.

- The button

opens the Technical Catalogs Management framework, which allows the entry of the catalog page or the profile data sheet.

opens the Technical Catalogs Management framework, which allows the entry of the catalog page or the profile data sheet.

- The button

allows to export the contents of the current framework to a spreadsheet format document (e.g., Excel). More information on using this feature can be found in the dedicated page

allows to export the contents of the current framework to a spreadsheet format document (e.g., Excel). More information on using this feature can be found in the dedicated page

Section 2: The fields of work

- Name

: Opens the Select machinings frame where we can select the machining, whose name is reported in this field.

: Opens the Select machinings frame where we can select the machining, whose name is reported in this field.

- Desc: Describes the selected machining.

- Offset: The function of this box is to determine a shift in the shares in the machining.

- Profile component type

: In the case of a composite profile, this function allows you to determine which component to apply the machining to.

: In the case of a composite profile, this function allows you to determine which component to apply the machining to.

- Condition

: This box is combined with a button that opens a large list of variables that indicate to the program, for example on which side of the typology the machining should be applied, the profile size; It is also possible to set a size range of the type within which the machining shall be applied.

: This box is combined with a button that opens a large list of variables that indicate to the program, for example on which side of the typology the machining should be applied, the profile size; It is also possible to set a size range of the type within which the machining shall be applied.

- Position

[Determines the position of the machining in the profile (Left = left of the profile/ None = central machining/ Right = right of the profile).

[Determines the position of the machining in the profile (Left = left of the profile/ None = central machining/ Right = right of the profile).

- From the right: The machining position is taken from the right, compensating for any possible cutting errors.

- Mirror machining: if enabled, it mirrors the working

- The

button opens the Machining operations

button opens the Machining operations