Profiles

From Opera Wiki

Revision as of 09:37, 11 May 2011 by Fabrizio.Loddo (Talk | contribs)

Contents |

Section 1: general information

- Name : The profile code given by the manufacturer or supplier.

- Master name:The profile code to be referred to.

NOTE:

NOTE:

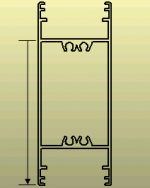

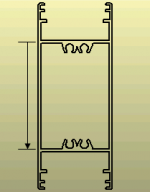

A typical example for which it is necessary to use the Master name is when a marine glazing sash sill profile can also be used as transom. In this case, their dimensions (encumbrance) will change when their use is modified. If we look at the following pictures we can see that the profile in Picture 1, called 9963 in this example and usually used as a sash sill, has a smaller encumbrance if used as transom, Picture 2.

This is necessary for loading a new profile that we will call k390-T. This will be an exact copy of the other one, except for changes to the type of use and chamber values . It would be useful to enter k290M as (Master Name) so that 9963 is used for the order to the supplier, in cutting lists, in optimisation lists, etc., rather than the 9963-T, which is only a fictitious profile.

NOTE:

NOTE:

If the profile purchase price relates to the range to which the item belongs, linking the range to the profile is very important to calculate its cost. In this case, if the name of the range is not indicated against the profile, it will not be possible to calculate the cost.

- Description: The text describing the characteristics of the profile.

Section 2: buying information

- Supplier : Indicates the name of the profile supplier

- Weight: The weight of the profile is indicated per metre length.

- Type

: This is a basic description indicating the type of material used to make the profile.

: This is a basic description indicating the type of material used to make the profile.

N.B: Selecting PVC will activate the field Assembly dimension, in which the quantity of the profile consumed during welding is indicated. This value is required to output an accurate cutting list.

N.B: Selecting PVC will activate the field Assembly dimension, in which the quantity of the profile consumed during welding is indicated. This value is required to output an accurate cutting list.

Section 3: Assembled profile information

An Assembled profile is made up of different bars, often from different materials, combined together to create the assembled functional profile (or assembled profile). For example, aluminium-wood profiles are usually made up assembling different bars: an aluminium bar, a plastic bar and a wood bar; also bicolour profiles are made with two aluminium bars with different colours. Opera allows the calculation of the assembled profile cost in addition to the calculation of the cost of each single component, even if they have different measurement units amongst them. In case of bicolour profiles, it calculates the cost of the internal and external colours. The programme can output in the materials list the assembled profile code or the codes of every single profile.

Enabling Assembled field will activate the following fields and the button ![]() .

.

- List of components: : If enabled, the profile component will be displayed in the part lists.

- Taglio componenti: Components cutting

- Screw: the screw accessory to use when assembling the profile

- Screw thread: average distance between screws. Opera will automatically calculate the required screw number.

Sezione 4: Warehouse and report information

- Exclude from lists : If enabled, the profile will be included in any print (cutting list, optimized cutting, supplier orders...)

NOTE:

NOTE:

This function can be used when the profile has the function of false profile with the sole purpose of creating an encumbrance in the typology. In this case, it should not appear in any print-out. Being in fact a fictitious profile, it is therefore necessary to check this box.

- Colour. (colouring)

: the color to assign to the profile inside the job. (Normal,Internal,External,Accessories,Shutter,Panes,Lock,Hinge,Hardware,Wall support,Sash. Int. / Ext color,Glazin bead,Gasket)

: the color to assign to the profile inside the job. (Normal,Internal,External,Accessories,Shutter,Panes,Lock,Hinge,Hardware,Wall support,Sash. Int. / Ext color,Glazin bead,Gasket)

- Bar length: The length of the entire bar.

- Reversible: If enabled, the profiled will be considered as reversible.

NOTE:

NOTE:

this option is used with Z-profiles that can be used in the same way even if turned upside down. This property will be used by the program when calculating the optimised cut, avoiding the unnecessary waste.

- Symmetric : the profile will be considered as symmetric in comparison with either the external and the internal surface.

- Min leftover: the smalles reusable leftover

Section 5: Technical information

- Height : the height of the profile measured perpendicular to its depth..

N.B: In case of fixed frames, moving frames, and T beams, the sum of the clear space + glazing rebate + rebate is given.

N.B: In case of fixed frames, moving frames, and T beams, the sum of the clear space + glazing rebate + rebate is given.

- Ignore col. thk. (ignore colour thickness): the program will include the thicknesses of the finishe when calculating cutting lists

- Core overhang: the distance between core and outer edge of the profile

- Assembly dimension: the dimension to add to the cut lenght for welding (used with PVC profiles only)

- Cutting step : the average cutting step

NOTE:

NOTE:

This is mainly used when cutting reinforcing for PVC profiles. If, for example, a step of “50 mm” is set, this will avoid the inclusion of decimal values on the cutting list. It will also allow the program to include all cuts that fall within the step value set beforehand. It is also important to note that this function always rounds off “downwards”.

- Always at 90° in enabled, the cutting on the profile will always be at 90°

- Function: the function(s) of the profile. Opera will consider these information for the cut calculations.

- Encumbrance: the encumbrance size

- Clrnc (clearance): the clearance size

- End mill corr (end mill correction): the end milling correction value

: opens profle prices window.

: opens profle prices window.

: opens profile cross sections window.

: opens profile cross sections window.

: opens standard profile accessories window.

: opens standard profile accessories window.

: opens profile machinings window.

: opens profile machinings window.

: opens profile optimization parameters.

: opens profile optimization parameters.

: apre il quadro di gestione superfici finitura del profilo.

: apre il quadro di gestione superfici finitura del profilo.

: opens a new archive to set up the assembled profile components

: opens a new archive to set up the assembled profile components

apre il quadro di gestione prezzi listino del profilo selezionato. Il pulsante è attivo solo in presenza di una revisione listino.

apre il quadro di gestione prezzi listino del profilo selezionato. Il pulsante è attivo solo in presenza di una revisione listino.