Accessory machinings

From Opera Wiki

(Difference between revisions)

Luca.cadeddu (Talk | contribs) |

|||

| (2 intermediate revisions not shown) | |||

| Line 4: | Line 4: | ||

'''Content description''': | '''Content description''': | ||

| - | *'''Name'''[[File: | + | *'''Name''' [[File:tastoc.png]]: the machining to assign to the profile |

*'''Autom''':a set of automatic operations that Opera can manage to choose from. The machining cost will be automatically calculated. | *'''Autom''':a set of automatic operations that Opera can manage to choose from. The machining cost will be automatically calculated. | ||

| + | **''None'': there is no specific condition to use the item, so the software will use it in any case. Please note that also setting a variable can affect whethere the accessory is applied or not | ||

| + | **''Connection bar contact'': this is used when the machining is related to the lock contacts where the connection bar insert when the casement is closed. this machining is usually linked to the Connection bar hardware | ||

| + | **''3RD closure contact'': an additional contact is usually mounted on the sash side where the lock is, usually for security locks. The machining is usually linked to the sash, and instructs the software that the sash profile next to the lock should contain a 3rd closure. Using formula you can setup the right condition for the exact position of the machining | ||

| + | **''Bearing plate'': the machining using this automation is linked to the lock hardware, and is used to setup a machining for the bearing plate located in front of the sash profile (can be either a mullion or a frame). | ||

| + | **''Contact'': this is used to setup machining for keepers related to the lock. The machining will be executed to the profile located in front of the lock. Each keeper involved will require a new machinining with "contact" automation and a set of rules/variables for the right positioning along the profile | ||

| + | **''Mullion Hole'': this automation is linked to the mullion support hardware. the machining is executed on the sash profile where the mullion is connected to | ||

| + | **''Band lock'': this is used only on band lock hardware, the machining is executed on the profile containing the lock | ||

| + | **''Push Handle'': push handle requires holes on both vertical sash profiles, this automation indicates the position of the two holes according to the lock position. | ||

| + | **''Opposite profile'': this is a general automation used on hardware which require a machining on the opposite profile the one containing the hardware itself | ||

| + | **''Hardware screw'': this is used for hardware screws, usually associated with conditions on height and width of the sash with variables Hia and Lia | ||

| + | **''Shutter hinge'': this is used for shutters requiring machining both on vertical and horizontal sash profile | ||

| + | **''Shutter hinge 3rd sash'': same as above but specific for 3rd sash on shutters | ||

| + | **''Hardware trimming'': machining to calculate the measure to cut the hardware accessory | ||

| + | **''Hardware striker slot'': this is used for machining of hardware installed on striker slot, machining must be added multiple times with condition and rules for a correct positioning according to the height of the items | ||

| + | **''Opposite profile (opposite ref.)'': same as opposite profile, but the reference point of the machining will be referred to the receiving profile | ||

| + | **''Gasket cut'': automation related to machining for gasket cut | ||

| + | **''Secondary hardware screws'': this automation is used to manage machining for corners of perimetral hardware. This only work for hardware items having position Head/R or Sill/L | ||

| + | |||

| + | |||

| + | |||

*'''Desc''': the machining description. | *'''Desc''': the machining description. | ||

* '''Offset''': the machining offset. (set positive values for bottom/right offset and negative for top/left offsets) | * '''Offset''': the machining offset. (set positive values for bottom/right offset and negative for top/left offsets) | ||

| Line 12: | Line 32: | ||

*'''All through''': if enabled, the machining will be added to the profiles on the same side | *'''All through''': if enabled, the machining will be added to the profiles on the same side | ||

*'''Structure all through''': if enabled, the machining will be added to the profiles on the same side and to the structure beside | *'''Structure all through''': if enabled, the machining will be added to the profiles on the same side and to the structure beside | ||

| - | *''' | + | *'''Position ''' [[File:frecciagiu.png]]: the machining posizion (left = left side of the profile, right = right side of profile, none = central machining) |

| - | + | *'''From the right''': the machining position is drawn from the right compensating possible cutting errors | |

| - | *''' | + | *'''Profile component type''' [[File:frecciagiu.png]]: sets the profile to which assign the machining when the selected profile is an assembled one. |

| - | + | ||

| - | *''' | + | |

| - | + | ||

<!-- HELP: JM/W2368--> | <!-- HELP: JM/W2368--> | ||

[[Category: JM/Manual]] | [[Category: JM/Manual]] | ||

Latest revision as of 08:16, 3 August 2023

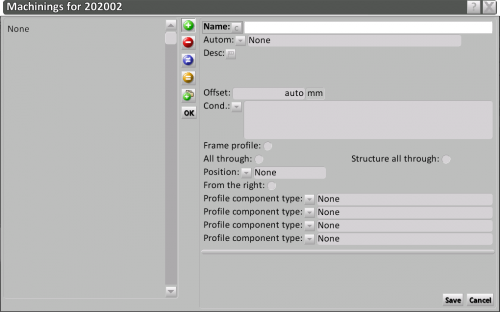

Content description:

- Name

: the machining to assign to the profile

: the machining to assign to the profile

- Autom:a set of automatic operations that Opera can manage to choose from. The machining cost will be automatically calculated.

- None: there is no specific condition to use the item, so the software will use it in any case. Please note that also setting a variable can affect whethere the accessory is applied or not

- Connection bar contact: this is used when the machining is related to the lock contacts where the connection bar insert when the casement is closed. this machining is usually linked to the Connection bar hardware

- 3RD closure contact: an additional contact is usually mounted on the sash side where the lock is, usually for security locks. The machining is usually linked to the sash, and instructs the software that the sash profile next to the lock should contain a 3rd closure. Using formula you can setup the right condition for the exact position of the machining

- Bearing plate: the machining using this automation is linked to the lock hardware, and is used to setup a machining for the bearing plate located in front of the sash profile (can be either a mullion or a frame).

- Contact: this is used to setup machining for keepers related to the lock. The machining will be executed to the profile located in front of the lock. Each keeper involved will require a new machinining with "contact" automation and a set of rules/variables for the right positioning along the profile

- Mullion Hole: this automation is linked to the mullion support hardware. the machining is executed on the sash profile where the mullion is connected to

- Band lock: this is used only on band lock hardware, the machining is executed on the profile containing the lock

- Push Handle: push handle requires holes on both vertical sash profiles, this automation indicates the position of the two holes according to the lock position.

- Opposite profile: this is a general automation used on hardware which require a machining on the opposite profile the one containing the hardware itself

- Hardware screw: this is used for hardware screws, usually associated with conditions on height and width of the sash with variables Hia and Lia

- Shutter hinge: this is used for shutters requiring machining both on vertical and horizontal sash profile

- Shutter hinge 3rd sash: same as above but specific for 3rd sash on shutters

- Hardware trimming: machining to calculate the measure to cut the hardware accessory

- Hardware striker slot: this is used for machining of hardware installed on striker slot, machining must be added multiple times with condition and rules for a correct positioning according to the height of the items

- Opposite profile (opposite ref.): same as opposite profile, but the reference point of the machining will be referred to the receiving profile

- Gasket cut: automation related to machining for gasket cut

- Secondary hardware screws: this automation is used to manage machining for corners of perimetral hardware. This only work for hardware items having position Head/R or Sill/L

- Desc: the machining description.

- Offset: the machining offset. (set positive values for bottom/right offset and negative for top/left offsets)

- Cond.

: athe condition to be set for performing the operations

: athe condition to be set for performing the operations

- Frame profile: if enabled, the machining will be put within the frame

- All through: if enabled, the machining will be added to the profiles on the same side

- Structure all through: if enabled, the machining will be added to the profiles on the same side and to the structure beside

- Position

: the machining posizion (left = left side of the profile, right = right side of profile, none = central machining)

: the machining posizion (left = left side of the profile, right = right side of profile, none = central machining)

- From the right: the machining position is drawn from the right compensating possible cutting errors

- Profile component type

: sets the profile to which assign the machining when the selected profile is an assembled one.

: sets the profile to which assign the machining when the selected profile is an assembled one.