How to manage the step Integrated flat optimization

From Opera Wiki

We define flat optimization as that function that allows the cutting of glass panes and panels to be optimized.

Contents |

Accessories archive: parameter settings of fills

The filling in Opera Gestione Commesse is loaded into the Accessories Archive respecting technical parameters essential for the correct use of the accessory (usage and unit of measurement).

- Usage is set by choosing the type Filling.

- The unit of measurement is set in m2.

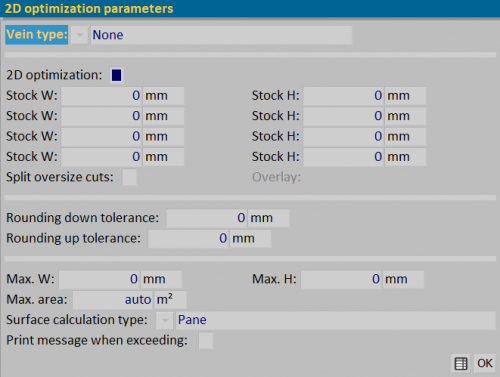

Accessories archive: optimization parameter settings

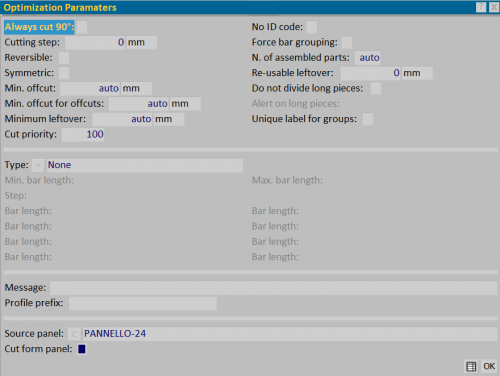

Through the File:KeyToptimizationForms.png button, if the module is active, we define the slab data in the Flat Optimization Parameters framework.

Below is the procedure for setting data for plate optimization:

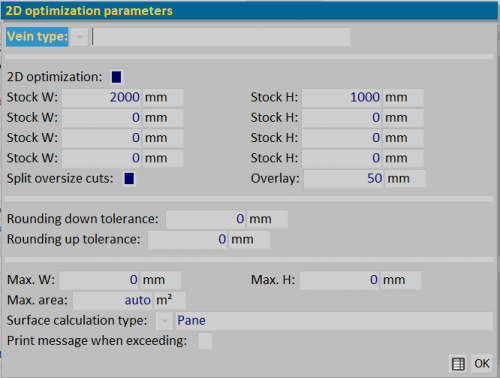

- Set in the field Vein type

the veins of the slab in the file (None, Horizontal Vein, Vertical Vein). The vein definition is related to the management of the slab cut type.

the veins of the slab in the file (None, Horizontal Vein, Vertical Vein). The vein definition is related to the management of the slab cut type.

- Activate the field Flat optimization to have way to indicate the size of the slab to be optimized in the L slab/H slab fields.

- L lastra/H lastra: Define slab optimization measures (up to 4 fields).

- Les champs Fractionnement surdimensionné et Chevauchement interviennent pour la gestion des profils presso-pliés (utilisés, par exemple, dans Façade continue). L'activation du premier champ permet de diviser les coupes au-delà de la dimension de la dalle que l'on choisit d'utiliser ; le second champ permet d'indiquer, le cas échéant, le degré de chevauchement des pièces divisées.

At this point our panel is ready for cutting.

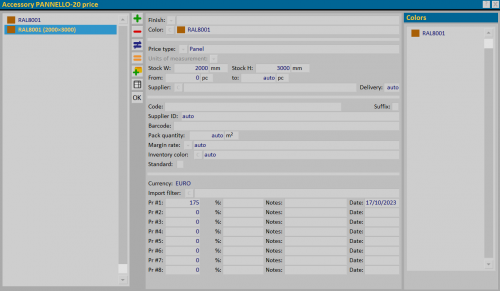

Accessories archive: price definition

It is possible to define a price per fill in the price panel that opens when the File:Keyprices.png button is pressed.

- We enter the standard price per m2, keeping in the field Type prz

the Standard type.

the Standard type.

- We enter a second price for the plate by choosing in the field prz type

the type Panel

the type Panel

- We indicate in the fields L slab and H slab the size of the slab with which to associate the price.

Job management: the optimization of slabs

After creating the job order with the panels and/or glass to be optimized, we can analyze the bill of materials and technical prints.

The Material framework of the order

There is a new File:Tastolastre.png button in the Job Material panel that allows you to develop the material into pieces considering the size of the slab.

The price per m2 is still present if we disable the File:Tastolastre.png button.

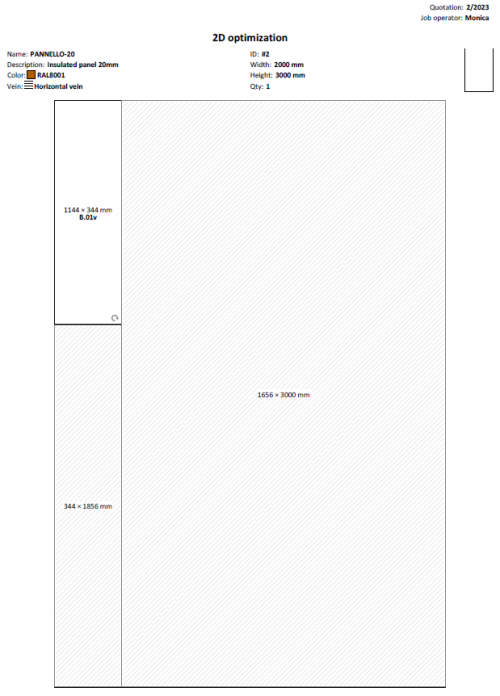

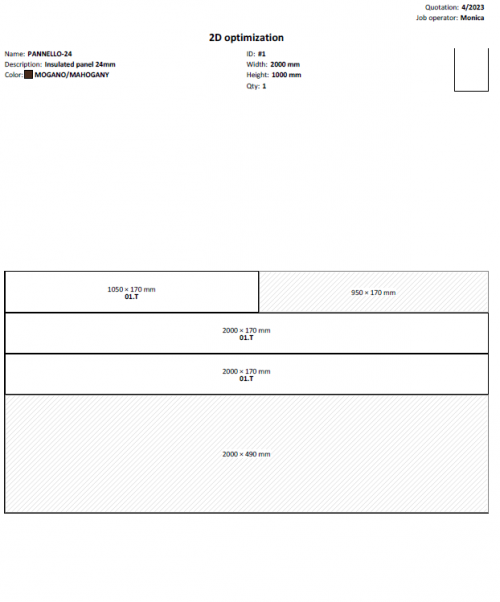

The Optimized Print

To see the optimized printing of the plate, from the Print Options panel we select the item Flat Optimization and print.

The paper indicates:

- the number of slabs to be optimized

- the relevant dimensions to be produced

- the part id code to determine the position in the job order

- the size of the waste

- the vein of choice in the archives

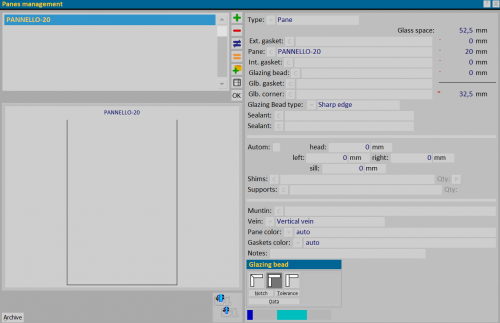

- the vein can also be set in the fill entered in the individual types in the job order. In this case an arrow appears in the printout on the panel indicating that it has been turned. The vein can be set in the panel for Filling management, in the appropriate field.

The fields Outsize divide and Overlap: example

The fields allow us to set the necessary parameters for optimization of the presso-bent profiles.

- In the Profile Archive, we select the profile to be used in the Optimization.

- Let's open the Optimization Parameters panel, through the File:Key-optimization2.png button

- We indicate in the Optimization Parameters frame of the profile, which is the source panel to get the profile from, activate the field to generate the cut for the panels, and record.

- In Accessor Archive, we select the source panel matched to the profile in Profile Archive.

- Let's open the Flat Optimization Parameters framework, through the File:Key-optimization.png button.

- In the Flat optimization parameters panel, we activate the Flat optimization field and set the plate size.

- We select the Divide outsize field, to divide the cuts beyond the sheet size, and the Overlap field, to indicate by how much the cut pieces overlap each other.

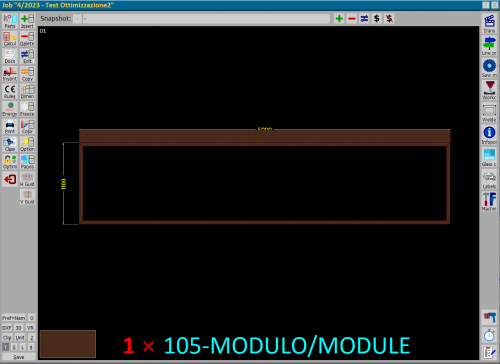

- In the Job Order, we enter the type we need to produce and enter the profile we prepared in the Archive.

- Let's run Flat Optimization, and print. The program will calculate how many profile pieces need to be made from the plate following the parameters set, as seen above.