2D Optimization

From Opera Wiki

(Difference between revisions)

Monica.Sanna (Talk | contribs) (→Section 3: Fields for message handling and fill size) |

Monica.Sanna (Talk | contribs) (→Related entries) |

||

| Line 41: | Line 41: | ||

*”’Print message when exceeding”’: If active, prints an error message when the pane exceeds the maximum size. | *”’Print message when exceeding”’: If active, prints an error message when the pane exceeds the maximum size. | ||

| - | == Related | + | == Related items == |

*[[How to manage Optimization 2D]] | *[[How to manage Optimization 2D]] | ||

Revision as of 16:15, 8 November 2023

The purpose of this archive is to manage the size limits of the fill and the messages in the prints.

It also allows you to manage the integrated Flat Optimization, if the corresponding step is activated.

Contents |

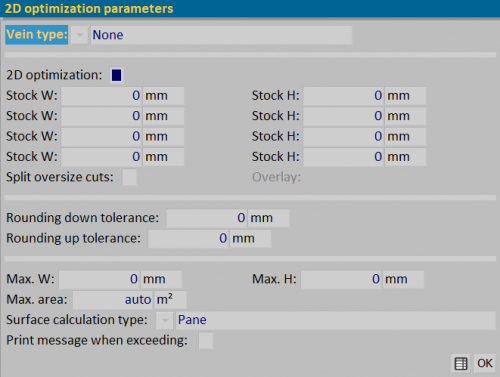

Section 1: the vein setting

- Vein type

: field for the choice of the type of vein filling (None, Horizontal Vein, Vertical Vein) and is related to the cutting management of the sheet. It’s a valid field whether you handle the filling in m2 or in pieces. In the first case, in the Fill List, the order can contain, if set both the type of vein and its dimensions. In the second case, we talk about Flat plate optimization, so check the dedicated section.

: field for the choice of the type of vein filling (None, Horizontal Vein, Vertical Vein) and is related to the cutting management of the sheet. It’s a valid field whether you handle the filling in m2 or in pieces. In the first case, in the Fill List, the order can contain, if set both the type of vein and its dimensions. In the second case, we talk about Flat plate optimization, so check the dedicated section.

Section 2: Fields for integrated 2D optimization

- 2D optimization (optional step): If enabled, it optimizes for this pane based on the dimensions set in the following fields.

- Stock W/StockH: width and height of the pane to be optimized.

- Split oversize cuts: divides cuts beyond the size of the sheet. The 2D optimization performed on the basis of the dimensions of the sheet set in the fields Stock W and Stock H is calculated in pieces. The parts of the sheet that exceed the set measurements are divided and calculated in m2.

- Overlay: field to set the overlap size of the split pieces.

Section 3: Fields for message handling and fill size

- Rounding down tolerance/Rounding up tolerance: in this field we define the tolerance in rounding (down or up) of the dimensions of the pane. The fields are useful in the dimensioning of pane on tipologies with multiple structures ( e.g. a window wall) that by their design are composed of different structures in different sizes. Indicating the tolerance for fillings allows you to size them all to the same dimension.

- Max. W/Max. H: maximum dimensions of pane.

- Max. area”’: maximun area per cut for automatic muntin configurations.

- Surface calculation type

: indicates which surface is taken into account for the calculation (Pane, Exposed area)

: indicates which surface is taken into account for the calculation (Pane, Exposed area)

- ”’Print message when exceeding”’: If active, prints an error message when the pane exceeds the maximum size.