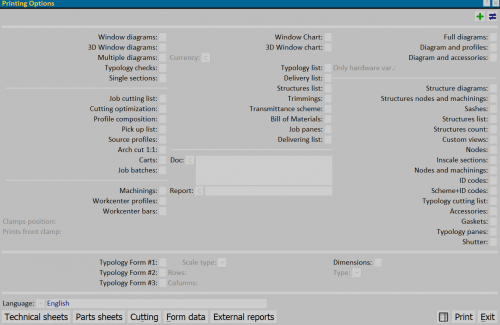

Job Printing options

From Opera Wiki

Monica.Sanna (Talk | contribs) |

|||

| (11 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

| - | + | [[File:finestraopzionistampa_.png|500 px|thumb|right]] | |

| - | + | ||

| - | + | ||

| - | [[File: | + | |

This button is necessary to print the processing cards of the work order. Select the required checkboxes relative to the print-outs and press [[image:tastook.png]] to start the print process | This button is necessary to print the processing cards of the work order. Select the required checkboxes relative to the print-outs and press [[image:tastook.png]] to start the print process | ||

| Line 17: | Line 14: | ||

*'''Cutting optimization''': This print-out shows the optimised cutting list for all typologies of the work order. | *'''Cutting optimization''': This print-out shows the optimised cutting list for all typologies of the work order. | ||

| - | |||

<!-- | <!-- | ||

L’invio di queste due stampe tecniche è preceduto dal quadro Selezione profili liste di taglio: | L’invio di queste due stampe tecniche è preceduto dal quadro Selezione profili liste di taglio: | ||

| Line 57: | Line 53: | ||

'''Diagram and accessories''': unlke the previous one, this print displays the typologies diagram along with the accessories list | '''Diagram and accessories''': unlke the previous one, this print displays the typologies diagram along with the accessories list | ||

'''Only hardware's var''': this print is addressed for those who use the advanced step '''Timing + Machining''' and has the aim to point the worker who assembles the structure which items to mount according to the dimension. | '''Only hardware's var''': this print is addressed for those who use the advanced step '''Timing + Machining''' and has the aim to point the worker who assembles the structure which items to mount according to the dimension. | ||

| - | {{NB| only those items who comes from a Auto selection and depends on the variables ''Lia'' and ''Hia'' will be reported}} | + | :{{NB| only those items who comes from a Auto selection and depends on the variables ''Lia'' and ''Hia'' will be reported}} |

| - | + | ||

'''Custom views''': prints the custom views for the typologies | '''Custom views''': prints the custom views for the typologies | ||

'''Nodes''': prints the profile cross-section for each typology of the job. | '''Nodes''': prints the profile cross-section for each typology of the job. | ||

| - | |||

'''Id codes''': this print-out shows the identification codes to assemble the profiles. It is used to correctly assemble the profiles on the typology, even if the assembling is carried out by a person who is not an expert. It is necessary that during the cutting phase, every piece is marked with the identification code indicated in the optimised cut print-out. | '''Id codes''': this print-out shows the identification codes to assemble the profiles. It is used to correctly assemble the profiles on the typology, even if the assembling is carried out by a person who is not an expert. It is necessary that during the cutting phase, every piece is marked with the identification code indicated in the optimised cut print-out. | ||

| - | |||

'''Cutting list''': this print-out contains the same information as the previous one, except that the cutting list is relative to each typology of the work order, whereas the other one shows the overall cutting list for the work order. | '''Cutting list''': this print-out contains the same information as the previous one, except that the cutting list is relative to each typology of the work order, whereas the other one shows the overall cutting list for the work order. | ||

| - | |||

'''Accessories, Gaskets, Panes e Shutter''': these print-outs will show the accessories, gaskets, panes and roller shutters required for the work order. | '''Accessories, Gaskets, Panes e Shutter''': these print-outs will show the accessories, gaskets, panes and roller shutters required for the work order. | ||

| - | |||

'''Window typw form #1, #2, #3 / Scale type / Dimensions / Lines / Columns''': | '''Window typw form #1, #2, #3 / Scale type / Dimensions / Lines / Columns''': | ||

| - | * [[File:tastosetupstampe.png]]: opens the [[Technical sheets setup]] | + | * [[File:tastosetupstampe.png]]: opens the [[Technical sheets setup|technical sheets setup window]] |

| - | * [[File:tastotaglio.png]]: | + | * [[File:tastotaglio.png]]: opens the [[Cutting parameters|cutting parameters window]] |

| - | * [[File:tastodatimodulo.png]]: | + | * [[File:tastodatimodulo.png]]: opens the [[Form information|form information window]] |

| + | *[[File:+.png]] [[File:tastodiverso.png]]: these buttons open the panel [[Job reports management]] | ||

| - | <!-- HELP: JM/ | + | <!-- HELP: JM/W 2841--> |

[[Category: JM/Manual]] | [[Category: JM/Manual]] | ||

Latest revision as of 12:15, 21 May 2025

This button is necessary to print the processing cards of the work order. Select the required checkboxes relative to the print-outs and press ![]() to start the print process

to start the print process

Content desctiption

- Window diagrams: This print-out is necessary to obtain the diagram of the typology on a single page. There will be a print-out for every typology of the work order.

- Multiple diagrams: This print-out is necessary to obtain several diagrams on a single page. The print-out will have a max. of 4 typologies per page.

- Check window types: This sheet basically retakes the General info data, as a verification of the structure features.

Questa stampa riprende sostanzialmente le informazioni dei Dati generali tipologia, è una stampa di verifica delle caratteristiche del serramento.

- Cutting list: This print-out shows the non-optimised cutting list for all typologies of the work order.

- Cutting optimization: This print-out shows the optimised cutting list for all typologies of the work order.

- Machinings: This print-out shows the profile machinings of the job

- Arch cut 1:1: This print has the data of the final operation, namely to cut the additional measure with the correct deegre. The program will develop a sheet per angle.

-

NOTE:

NOTE:

In the printout the user has all the data he need to end the whole centering procedure. Furthermore as we see in the above example, the program put in the sheet the profile final edge, this feature is very useful for the user who’s going to cut, because the sheet can be laid upon the piece in order to set at best the machine parameters.

Carts: This function prints out a sheet with the carts layout with the relatives stocking box for remainders, according the setting made in the Cutting parameters.

Workcenter's profiles: this sheet displays profiles whom will pass in the workcenter, with the machining features.

Machine center bar: prints workcenter CAM machinings for the optimized bars

Clamps position: This printout displays Timing + Machining, where are displayed the profiles clamping features worked in the workcenter.

Window chart: prints out a chart of all the window types in the job. This report is suitable for commercial use, because it displays a detailed list of the costs and dimensions of the typologies.

List of window types: same as the above printout, but prices are not shown.

Delivering list: prints out the description of every typology without the scheme.

Transmittance scheme: prints out the structure diagrams with their thermal trasmittance.

Bill of materials: opens Printing parts order window

Panes: prints a order list of panes for the sctuctures within the quotation. It describes their dimensional features and quantity.

Document ![]() : the document from the archive to print with the job data.

: the document from the archive to print with the job data.

Complete diagrams: this print-out shows the complete processing list of the typologies, with the diagrams, the cutting list and all the required accessories. Diagram and profiles: same as adove, but the accessories list will not be shown in the printout Diagram and accessories: unlke the previous one, this print displays the typologies diagram along with the accessories list Only hardware's var: this print is addressed for those who use the advanced step Timing + Machining and has the aim to point the worker who assembles the structure which items to mount according to the dimension.

N.B: only those items who comes from a Auto selection and depends on the variables Lia and Hia will be reported

N.B: only those items who comes from a Auto selection and depends on the variables Lia and Hia will be reported

Custom views: prints the custom views for the typologies Nodes: prints the profile cross-section for each typology of the job. Id codes: this print-out shows the identification codes to assemble the profiles. It is used to correctly assemble the profiles on the typology, even if the assembling is carried out by a person who is not an expert. It is necessary that during the cutting phase, every piece is marked with the identification code indicated in the optimised cut print-out. Cutting list: this print-out contains the same information as the previous one, except that the cutting list is relative to each typology of the work order, whereas the other one shows the overall cutting list for the work order. Accessories, Gaskets, Panes e Shutter: these print-outs will show the accessories, gaskets, panes and roller shutters required for the work order. Window typw form #1, #2, #3 / Scale type / Dimensions / Lines / Columns:

-

: opens the technical sheets setup window

: opens the technical sheets setup window

-

: opens the cutting parameters window

: opens the cutting parameters window

-

: opens the form information window

: opens the form information window

: these buttons open the panel Job reports management

: these buttons open the panel Job reports management