Profile machinings

From Opera Wiki

(Difference between revisions)

| (3 intermediate revisions not shown) | |||

| Line 14: | Line 14: | ||

*'''Autom'''[[File:frecciagiu.png]]: a set of automatic operations that Opera can manage to choose from. The machining cost will be automatically calculated. | *'''Autom'''[[File:frecciagiu.png]]: a set of automatic operations that Opera can manage to choose from. The machining cost will be automatically calculated. | ||

| - | + | **''None'': There’s no particular condition which indicate the program how to apply the machining. | |

| - | + | **''Connection bar contact'': This parameter tells the program that this operation is to mount the contact plates for the locking bar. The machining will be applied on the frames either top and bottom, where the contact plate is fixed. | |

| - | + | **''3rd closure contact'': Sometimes the side who receive the sash with the handle, has mounted a further contact plate, specific for the third closure, or security closure. The machining with this parameter is usually charged to the handle. The machining will be calculated at the same height of the handle. The dimension can be conditioned using the fields offset or Condition. (see ahead in this section). | |

| - | + | **''Bearing plate'':The machining who has this parameter being applied to the lock, Bearing plate tell the program the machining goes in the frontal jamb opposite the lock. | |

| - | + | **''Contact'': This automatism is for the closing striker of a gear. It indicate the program the machining must be done in the frontal jamb opposite the gear. The machinig will be loaded as many times as the number of strikers. | |

| - | + | **''Mullion hole'':The machining to mount the mullion being applied to the staple, this parameter indicate the program this machining goes in the side which receive the mullion or transom | |

| - | + | **''Band lock'':This is for the lock to be mounted in the door band. The machining is loaded to the lock itself or the associated hanlde. The operation will be carried out in the transom. | |

| - | + | **''Push handle'': This is for the hanlde in the security doors, it require a hole in both the jambs of the sash where it is mounted. The automatism indicate the hole position according the hanlde height. | |

| - | . | + | **''Opposite profile'': This parameter allow to items saved as Assembly hardware, to apply the machining in the opposite profile where the hardware is loaded. |

| + | **''Screws'': It is asociated to the screw needed to fix the gear and the perimetral hardware. It works according the variable Hia and Lia. | ||

*'''Angle'''[[File:frecciagiu.png]]: the automatic operation angle. | *'''Angle'''[[File:frecciagiu.png]]: the automatic operation angle. | ||

Latest revision as of 13:57, 2 May 2014

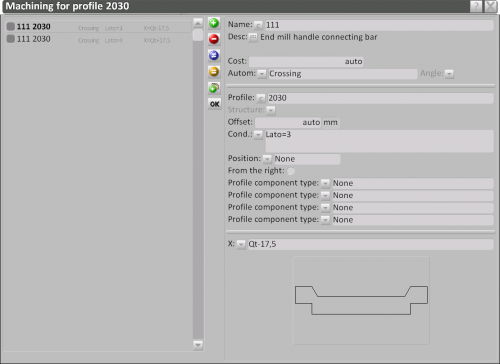

This windows allows to assign a set of machinings to the profile, along with their costs.

Content description

- Name

: the machining to assign to the profile-

: the machining to assign to the profile-

- Desc: the machining description.

- Cost: the machining cost. If left blank, Opera will calculate automatically the cost using values set in Company data

- Autom

: a set of automatic operations that Opera can manage to choose from. The machining cost will be automatically calculated.

: a set of automatic operations that Opera can manage to choose from. The machining cost will be automatically calculated.

- None: There’s no particular condition which indicate the program how to apply the machining.

- Connection bar contact: This parameter tells the program that this operation is to mount the contact plates for the locking bar. The machining will be applied on the frames either top and bottom, where the contact plate is fixed.

- 3rd closure contact: Sometimes the side who receive the sash with the handle, has mounted a further contact plate, specific for the third closure, or security closure. The machining with this parameter is usually charged to the handle. The machining will be calculated at the same height of the handle. The dimension can be conditioned using the fields offset or Condition. (see ahead in this section).

- Bearing plate:The machining who has this parameter being applied to the lock, Bearing plate tell the program the machining goes in the frontal jamb opposite the lock.

- Contact: This automatism is for the closing striker of a gear. It indicate the program the machining must be done in the frontal jamb opposite the gear. The machinig will be loaded as many times as the number of strikers.

- Mullion hole:The machining to mount the mullion being applied to the staple, this parameter indicate the program this machining goes in the side which receive the mullion or transom

- Band lock:This is for the lock to be mounted in the door band. The machining is loaded to the lock itself or the associated hanlde. The operation will be carried out in the transom.

- Push handle: This is for the hanlde in the security doors, it require a hole in both the jambs of the sash where it is mounted. The automatism indicate the hole position according the hanlde height.

- Opposite profile: This parameter allow to items saved as Assembly hardware, to apply the machining in the opposite profile where the hardware is loaded.

- Screws: It is asociated to the screw needed to fix the gear and the perimetral hardware. It works according the variable Hia and Lia.

NOTE:

NOTE:

this field is ebabled only when Contact is chosen in Autom. field..

NOTE:

NOTE:

this field is ebabled only when Contact,Crossing or Receiver is chosen in Autom. field..

NOTE:

NOTE:

this field is ebabled only when Structure is chosen in Autom. field..

- Offset: the machining offset. (set positive values for bottom/right offset and negative for top/left offsets)

- Position

: the machining posizion (left = left side of the profile, right = right side of profile, none = central machining)

: the machining posizion (left = left side of the profile, right = right side of profile, none = central machining)

- From the right: the machining position is drawn from the right compensating possible cutting errors

- Profile component type

: sets the profile to which assign the machining when the selected profile is an assembled one.

: sets the profile to which assign the machining when the selected profile is an assembled one.

Nel caso di un profilo composto, questa funzione consente di determinare su quale componete applicare la lavorazione. Se, ad esempio, si tratta di profili in Alluminio legno composti da un componente interno ed uno esterno.